How To Repair Deep Scratches On Alloy Wheels

Are you exploring flap discs to apply for your next project? Maybe you've been using grinding wheels all this fourth dimension and have overlooked the benefits of a flap disc. Flap discs are highly versatile tools and can meet your needs in a variety of applications — from stock removal to grinding and finishing. Many operators actually prefer flap discs over grinding wheels during operation, and when it comes to your next project, flap discs may exist just the solution you need.

Continue reading our flap disc buying guide to learn more near these tools and how to select the right flap disc for your project.

What Are Flap Discs?

Flap discs are made from multiple overlapping pieces of abrasives or 'flaps,' which is how they got their proper name. Flap discs are designed for right bending grinder applications ranging from heavy stock removal to surface blending and smoothen finishing.

While the first abrasive flap discs for high-speed angle grinders were developed towards the end of the 1970s and were somewhat bones, today's versions offering an array of diversity. You should strongly consider a flap disc over a grinding wheel if y'all need a superior finish and greater ease of utilize during operation.

Advantages of Flap Discs

Flap discs are versatile: they can grind, blend and stop. They are also lightweight, easy to maneuver, and require less change over fourth dimension. When performing a job, many operators prefer flap discs over grinding wheels due to lower vibration and noise levels. Plus, they offer cooler cutting with minimal scratching.

For case, grinding wheels have to be discarded even after a small area of annoying is worn out. Comparatively, flap discs remain useful fifty-fifty later on the flaps erode, which results in a longer operating life. Compared to a flap disc, grinding wheels are cheaper on a unit cost basis. Still, if you consider the versatility, durability and ease of utilise provided by flap discs, they are more price-effective in the long run. Considering of these advantages, the popularity of flap discs has soared in the last several years.

Shop past Brand

How to Select the Correct Flap Disc

When it comes to flap discs, there's a diversity of discs available in today'southward market. Allow's kickoff by agreement the various components of a flap disc, and then you know how to select the right disc for the right task:

Flap Disc Shape

Is stock removal your primary objective, or do you want a smooth finish? Choosing the right disc shape is the single-most of import variable, and the shape volition assistance yous effectively attain your results. Flap discs are almost always used on right bending grinders, and they are practical to your piece of work at an angle or parallel to it. Flap discs are available in ii shapes: conical or apartment-shape.

- Conical flap disc:Conical flap discs are your all-time friends when you lot need to remove a lot of material in a small corporeality of time. They can exist used for edge-working as well as on contoured applications. The flaps in a conical flap disc are angled. As a event, these discs offering a greater surface area for stock removal on horizontal surfaces.

- Flat flap disc:While conical discs are great for rapid stock removal, flat flap discs are best for blending and superior finishing. They are mostly used on flat surfaces. The flaps of a flap disc are adhered to a backing plate which provides stability during operation.

Flap Disc Material

The backing plate material is likewise an important variable to consider when choosing flap discs for your application. Fiberglass, plastic and metal are the nigh pop backing plate materials:

- Fiberglass:Being strong, durable, lightweight and safe, fiberglass is the most popular cloth selection. Fiberglass creates a stiff bond with adhesives and does not contaminate the working surface. This type of plate also gets consumed during use, and it absorbs vibration very well. Remember, fiberglass backing is fabricated out of layers of fiberglass that are mesh-bonded and pressed together. With more layers and a higher mesh density, the backing will be stronger and more durable — this is an of import consideration when y'all're examining the detailed specs of a flap disc.

- Plastic:Another popular backing cloth is plastic, and nylon is the about commonly used plastic. These backings tin can be trimmed which allow longer usage of flaps, specifically during blending and finishing. These days, plastic is becoming an increasingly attractive choice due to its conformability and costs.

- Metal:Metal backing plates are the safest option, and they're great when you need extra strength and house support. Aluminum is a usually used metallic. Since metallic plates are expensive, they should too be used where they brand the most sense. For example, when working with flap discs on physical or stone applications, use flap discs with metals for potent support and better performance. Metals don't get consumed during use, simply metal plates can be hands recycled when a flap disc is past its useful life.

Annoying Flap Densities

What does abrasive flap density mean? Retrieve of the density as the total amount of abrasive area provided by the flaps on a flap disc. This surface area depends on the quantity of flaps on a disc, their angle relative to the center of the disc and how far they are spaced. Recollect, each variable tin can impact the corporeality of disc surface area available to piece of work on your chore.

- Standard density: Standard density flaps are optimal for fast stock removal and heavy-duty applications.

- High density: High-density flaps are best-suited when working on curved or uneven jobs, too as during finishing. Don't take the description of flap disc density at face value. Consider the number of flaps, angle and spacing to differentiate between two discs, both of which may specify "standard density flaps" or "high-density flaps."

Annoying Grit Material

Flap discs tin be used for a variety of applications, whether information technology's metal or woodworking, concrete grinding or finishing, stone smoothing or finishing, paint or rust removal, and more. In order to get the maximum benefits out of flap discs, it's important to choose the right abrasive grit material for your specific job needs. Let's look at the nigh ordinarily used abrasive grit types:

- Ceramic Alumina:This material is slap-up for stainless steel or blend metals awarding. With Ceramic Alumina, the grit material ruptures at a micro level during operation. This produces a constant supply of sharp cut surfaces. As a result, it enables faster cutting while assuasive the entire grain to be used. As the unabridged grain is getting used up in the cut procedure, these discs offer higher immovability.

- Zirconia Alumina:This is a blend of Zirconia and Aluminum Oxide grain, and it's swell for carbon and mild steel awarding. Zirconia Alumina costs less than Ceramic Alumina, and it provides a not bad cutting rate for the cost.

- Aluminum Oxide: This is the original grit cloth used in the 1970s when flap discs were first introduced. It'southward also the lowest-cost option. Today, it is recommended for smaller jobs where the product beingness produced is low-value.

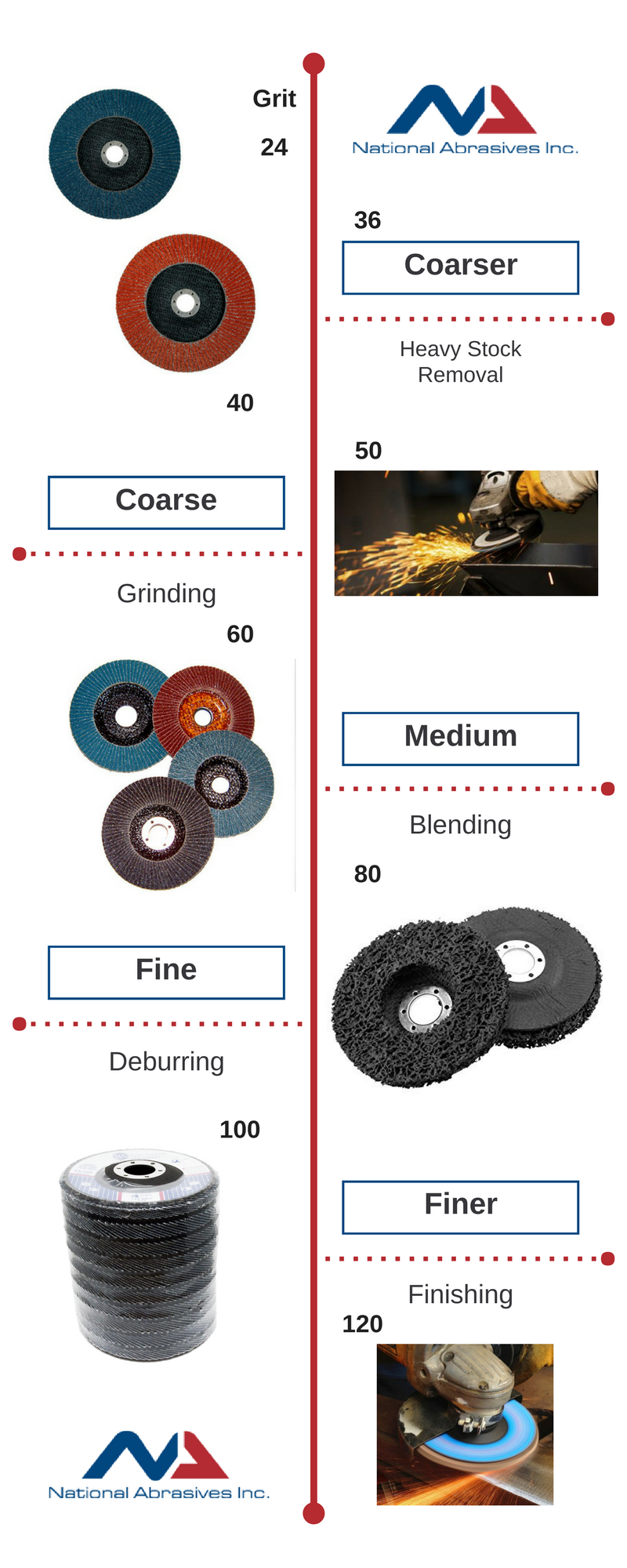

Grit Size

You're probably familiar with dust size if you've been using grinding wheels. Grit size is the final variable you accept to choose based on your ultimate goal and what you're trying to accomplish. For stock removal or common grinding, utilize abrasives with lower grit numbers. On the other end of the spectrum, use higher dust sizes if y'all're trying to accomplish polish finishing.

Flap Disc Grit Chart

Flap Disc Uses

Flap discs initially became popular for employ on metals, especially in welding applications. Today, various flap discs are bachelor to use for different surfaces:

- Flap discs for aluminum:Compared to other metals, aluminum has a lower melting temperature and melts easily. This causes the aluminum material to coat the flap disc during grinding, covering the dust and exposing only bits of aluminum. For stock removal, use a T29 conical disc at a xv-degree angle to provide maximum surface contact. If you need to surface-clean or provide a smooth finish, utilise a T27 flat disc that's parallel to your work area. For all-time results, utilize light and even pressure to optimize the grinding process and reduce loading.

- Flap discs for forest:Flap discs are slap-up tools for working on forest. The flap discs designed for utilize on wood are like in nature to the ones designed for utilise on metal. You lot tin can utilize aluminum oxide grits for wood applications. For wood, you should also use the flap discs on your angle grinder just like you would use a grinding wheel. In order to avoid deep scratches, outset with a heavy grit and work your way up to the lighter grits (100+) for a last finish. For wood sanding, work your mode through 120, 150, 180 and 220-grit sizes to achieve a furniture-grade surface.

- Flap discs for paint removal: Practice you have a metal object that's rusted but yous know you can still extend its life? Do you accept old, chipping pigment on your automobile that yous need to remove to give it a like-new appearance? Flap discs, especially non-woven discs, are ideal tools for removing pigment and rust. Non-woven flap discs, or the ones with aluminum oxide, can be used for pigment or rust removal applications. As with flap discs in general, these discs tin grind and finish in a single operation while offering a shine and controlled grind.

- Flap discs for concrete: You'll need silicon carbide or diamond flap discs for aggressive stock removal on concrete. Silicon carbide and diamond are some of the hardest materials in the world. Using these discs volition allow yous to piece of work on physical surfaces without the need for high pressure. These flap discs have rigid backings, and they tin likewise be used on other surfaces such as engineered stone, granite, marble and ceramics.

Getting Started With Your Flap Discs

Earlier you start using whatever shop tool, you should always make sure you:

- Sympathise your tool

- Read the user's transmission

- Wear the proper safety equipment

- Ensure a safe working area

- Know what y'all're using your tool for

With flap discs, y'all need to consider the size and scope of your project. Do you have to remove stock aggressively, or is smooth finishing your goal? Or practise you desire a grind that's somewhere in between? Whatever your respond, there'due south a flap disc that'south right for your situation.

Don't limit flap disc to the common metals. Flap discs can also exist used across various surfaces, including aluminum, wood, physical, engineered rock, granite and more than. For each of these applications, whether you're grinding or finishing, make sure you choose the right flap disc. Retrieve, conical shaped flap discs are not bad for stock removal and flat flap discs are best for finishing.

Flap disc backing material is important as it provides support during operation. Use metal backings for concrete or engineered stones, and utilize fiberglass or plastic backings for most metallic or wood jobs. Also consider your abrasive grit material, and cull your grit size to achieve the desired results. For common grinding, use abrasives with lower grit numbers. For smooth finishing, use higher dust sizes.

Using a flap disc instead of a traditional tool can greatly enhance the quality of your job. You can too benefit from lower noise and vibration. Flap discs can pb you to a world of new applications, while helping y'all achieve new levels of efficiency and effectiveness.

Purchasing Your Flap Discs

When it comes to purchasing flap discs, you lot have plenty of options. All the same, a reputable company that cares about you and your project will aid you feel a better result. You should too experience comfortable asking for samples when you're trying new tools like a flap disc.

National Abrasives, Inc. has a large variety of tools, accessories and supplies to encounter your firsthand needs and your needs in the future. We're a family owned visitor that offers aforementioned-24-hour interval shipping and discounted pricing for bulk orders. Scan our large selection of brand-proper name flap discs, including Walter Abrasives flap discs, along with angle and bench grinder tools and accessories. If you lot have any questions, our team can guide you to the correct tool for your specific task. Contact us today to get started!

Shop All Flap Discs Now

Larn More than About Abrasives & Flap Discs

- How to Use a Finishing Sander

- How to Sand & Refinish Hardwood Floors

- Sanders & Abrasives for Grinding Aluminum

- Flap Cycle & Disc Products

*Updated: Feb 20, 2022

Source: https://www.nainc.org/blog/how-to-select-the-right-flap-disc-for-your-project/

0 Response to "How To Repair Deep Scratches On Alloy Wheels"

Post a Comment