How To Repair A Carburetor On A 1998 Kawasaki 4 X 4 When It Runs Only On Choke

The Keihin CVK-40 Carburetor

The Intendance and Feeding Of Your Vulcan Carb

Part I - How It Works

THE BASICS - Mixing and Delivering

While most of the following information applies to all CV carbs, and to some extent all carb types, this commodity is specific to the Keihin CVK40 institute on many Kawasaki motorcycles (KLR's and Vulcans) forth with some Harleys. If you demand replacement parts yous'd be well advised to go them from your local Harley Davidson outlet. They will be less expensive than ordering through your Kawasaki dealer and, in most cases they volition exist 'in stock'.

The CVK40 is technically a bleed type carb, with a variable venturi that's controlled by abiding velocity (CV). It's as well known as Constant Low or Abiding Vacuum. The 40 in the proper noun represents a twoscore mm venturi exit diameter. Wonder why 'K'awasaki added the K...?

Drain Blazon CARBS - Let it Bleed

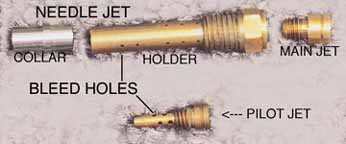

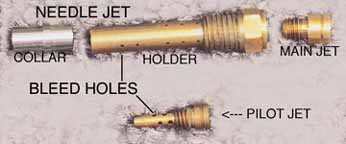

Almost carbs have a one piece needle jet. On the CVK40 information technology consists of a neckband and what Kawasaki calls a holder. Most 4-strokes accept pivot holes along the length of this brass jet. These pin holes allow air from the air jet to premix with fuel from the fuel jet to get-go the mixture emulsification procedure before it enters the venturi. Chief blazon carbs use a solid jet, (no pin holes).

VARIABLE VENTURI - Getting Sucked In

A venturi is a tube with a convex taper, (i stop wider than the other). As air enters the wider terminate it's squeezed into the narrower section of the tube, lowering the air'south force per unit area. The area of lowest pressure is just past the narrowest point and is called the depression. This has ever seemed counterintuitive to me, just Bernoulli'due south Principle outlines the fluid dynamics involved in this event. This lowered pressure level, or comparative vacuum is carve up from the engine vacuum. A variable venturi varies the venturi bore at the depression past raising or lowering an obstruction. This obstruction is called a slide. On a CV the slide is called a piston or diaphragm valve.

CV or SLIDE CARB - The Great Compromise

Both the CV and conventional slide carbs are classified as variable venturi carbs. The slide on a conventional carb is straight connected to the throttle cablevision. Twist the throttle grip and the slide is raised in the venturi. On a CV carb the throttle cable is connected to a butterfly valve that varies the volume through the venturi. It'due south not the throttle, it'due south the pressure difference from the venturi to the outside temper that moves the slide.

So which type is better? That depends on what you want to do. The manufacturers will tell you the CV is the next best matter to electronic fuel injection. It does feed a precise amount of mixture to smooth out throttle response, reduce pollution, and stretch your fuel budget and gas tank range.

This is slap-up for tarmac cruising and feeling warm and fuzzy about doing your part to reduce global warming while pocketing some spare change. It certain makes it easier for the manufacturers to get the EPA approval stamp on the cycle.

But what if you feel that no matter how much you hop upwardly your little fauna, you're never going to match the belching of that cager in the gas guzzling V-12 ? What if you don't listen spending more for gas, and when you go off-road y'all want a burst of power to blip over obstacles or steer through a wash without fanning your clutch while waiting for the vacuum to build in the venturi? If you tin can subject area yourself to control the throttle so that you lot don't bog your engine, and so you desire a conventional slide carb.

40 MM -Size Matters

MIXING AIR AND FUEL - All In the Pressure

Information technology all starts in your engine. Call back of your thumper as a big pump, happily sucking and bravado down the route. During the intake stroke the engine'southward piston descends in the cylinder. This creates a void that sucks in whatever is on the other side of the open engine intake valves.

Unless the engine intake valves are open, the carb is non being sucked on by the engine. This vacuum action powers the carb.

Look at the 4-cycles of our iv-stroke thumperpumper.

Look at the 4-cycles of our iv-stroke thumperpumper.

- Intake - piston pulls down sucking mixture in.

Intake valves open, exhaust closed. - Pinch - piston goes up.

Intake and exhaust valves airtight. - Ignition/Power - piston forced downwardly.

Intake and exhaust valves airtight. - Exhaust - piston goes up blowing out burned gas.

Exhaust valves open, intake closed.

Each time the piston goes up and downward, (two of the 4 strokes), one revolution has occurred. It takes two revolutions to complete the four strokes, or one-half of a revolution to complete ane of the iv strokes. At redline, your engine is sucking on the carb at a charge per unit of over sixty times per second. At idle it's around xi times a second. The math below shows that with a 651cc deportation, a theoretical maximum of between vii and 40 liters of mixture are sucked in each 2d.

7500 .......(engine RPM)

/ 2 ...........(2 revs per intake stroke)

= 3750 .....(intake strokes per minute)

/ sixty .........(seconds per minute)

= 62 ........(intake strokes per 2d)

x .651 ......(engine displacement in liters)

= xl.69 ....(liters per 2d)

These numbers assume 100% efficiency. Mister_T calculates about 38% efficiency at idle. So these numbers are only to illustrate the relative difference in volume from idle to redline.

Remember Bernoulli's effect in the venturi? Sitting below the venturi is the fuel float chamber which is vented to the outside of the carb to lucifer atmospheric air pressure. The fuel in the float basin is also 'vented' to the low force per unit area of the venturi through the starter, airplane pilot and main fuel jets.

So you can think of the float chamber as being pressurized in comparison to the partial vacuum of the venturi. The fuel naturally tries to make full in the low pressure of the venturi's depression by injecting itself through i, or a combination of the three fuel jets.

THE ODDS - Skinny or Fatty

Any carb trouble boils down to either it's too rich, (too much fuel or besides trivial air), or information technology'due south as well lean, (too much air or too petty fuel). The 'mixture', (a mixture of fuel and air, your engine'southward 'food'), is theoretically platonic at effectually 15 parts of air to i part of gasoline by weight, (not volume). The outer limits are 12:1 and 18:i.

Any carb trouble boils down to either it's too rich, (too much fuel or besides trivial air), or information technology'due south as well lean, (too much air or too petty fuel). The 'mixture', (a mixture of fuel and air, your engine'southward 'food'), is theoretically platonic at effectually 15 parts of air to i part of gasoline by weight, (not volume). The outer limits are 12:1 and 18:i.

Too rich and you're wasting fuel, spewing more pollutants, diluting your oil, fouling engine parts, and performance suffers. Too lean and yous run the adventure of detonation, engine operating at college temperatures, and functioning suffers.

An air-cooled engine needs to run richer (more fuel) to aid in engine cooling. This is another plus of our water-cooled system to balance out it's disadvantages.

PARTS - Is Parts

Supplementing the factory manuals, the following text and photos should make it easier to understand how the carb works. The parts are broken into the post-obit groups:

Bladder System - You're Floating In It

Bladder System - You're Floating In It

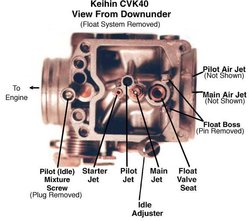

The float system acts every bit a fuel reservoir to meet engine demand. The bladder is hinged on a pin in the float boss. It rises and falls with the fuel level in the float bowl. The minor metal tang integrated in the plastic float supports the float valve, aka float needle. As the fuel in the bladder basin rises, the float valve is pushed into the valve seat, until information technology'due south high plenty to shut off the fuel period to the bowl. The level in the basin drops lowering the float which pulls the float valve from information technology'south seat, and fills over again.

The float system acts every bit a fuel reservoir to meet engine demand. The bladder is hinged on a pin in the float boss. It rises and falls with the fuel level in the float bowl. The minor metal tang integrated in the plastic float supports the float valve, aka float needle. As the fuel in the bladder basin rises, the float valve is pushed into the valve seat, until information technology'due south high plenty to shut off the fuel period to the bowl. The level in the basin drops lowering the float which pulls the float valve from information technology'south seat, and fills over again.

TARTER ENRICHER - KLR Forenoon Coffee

TARTER ENRICHER - KLR Forenoon Coffee

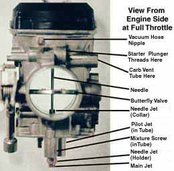

This system is referred to equally the choke. Merely that's a misnomer. When you utilise the choke lever, what you're doing is retracting a plunger that opens a tube connected to the starter jet, allowing additional fuel to enter the venturi just below the vacuum hose nipple. Information technology supplements the pilot organisation at start upwards.

This system is referred to equally the choke. Merely that's a misnomer. When you utilise the choke lever, what you're doing is retracting a plunger that opens a tube connected to the starter jet, allowing additional fuel to enter the venturi just below the vacuum hose nipple. Information technology supplements the pilot organisation at start upwards.

PILOT System - Steering You to Amend Lows

The master purpose of the pilot organization is to supply the mixture at idle. It continues to supply fuel throughout the entire throttle range, merely subsequently about 1/viii throttle is reached the MAIN Arrangement starts to put out an increasing percentage of the total mixture up to full throttle.

The master purpose of the pilot organization is to supply the mixture at idle. It continues to supply fuel throughout the entire throttle range, merely subsequently about 1/viii throttle is reached the MAIN Arrangement starts to put out an increasing percentage of the total mixture up to full throttle.

When you ready the idle with that large screw on the right side of the carb, what y'all're doing is covering or uncovering one or more of the iv small holes that are drilled into the venturi, (leading to the pilot jet) simply under the butterfly valve, and letting more or less air pass the butterfly. When y'all arrange the pilot screw that'southward under the carb, you lot are varying the amount of air premixing with the gas before information technology enters the venturi.

Principal System - The Meat

As you advance the throttle cable that'southward connected to the butterfly valve, the butterfly opens to let more than air through the venturi. This increases the vacuum event that is transferred up through the vacuum drilling (the hole you bored out for the Dynojet kit), on the diaphragm valve (slide), that leads to the TOP diaphragm sleeping room.

As you advance the throttle cable that'southward connected to the butterfly valve, the butterfly opens to let more than air through the venturi. This increases the vacuum event that is transferred up through the vacuum drilling (the hole you bored out for the Dynojet kit), on the diaphragm valve (slide), that leads to the TOP diaphragm sleeping room.

The top chamber is separated from the Bottom chamber by the condom diaphragm. The lesser chamber is open up to atmospheric pressure from the airbox by the crescent shaped casting on the top of the venturi. When the vacuum in the superlative bedchamber rises sufficiently, the constant ambient pressure of the lower sleeping accommodation, helps the diaphragm valve overcome the downwardly forcefulness of the diaphragm bound, and it rises from the venturi.

The top chamber is separated from the Bottom chamber by the condom diaphragm. The lesser chamber is open up to atmospheric pressure from the airbox by the crescent shaped casting on the top of the venturi. When the vacuum in the superlative bedchamber rises sufficiently, the constant ambient pressure of the lower sleeping accommodation, helps the diaphragm valve overcome the downwardly forcefulness of the diaphragm bound, and it rises from the venturi.

As the diaphragm valve is raised from the venturi depression (lowest pressure area), the needle is pulled further out of the needle jet, exposing a thinner portion of the needle taper which allows even more fuel to ascent into the venturi to meet the increased engine demand.

COASTING ENRICHER - Feeding a Airtight Mouth

You're blasting down the trail and yous run across a hairpin coming up, and so you shut the throttle. This closes the butterfly valve. Yous and your 400lb baby (the bike, non the other love of your life), are still rolling with inertia, keeping the engine revs high. Now it can't become the mixture it's trying to suck in because the butterfly valve is airtight, blocking the air catamenia. To compensate for this there's an air jet in the lower

You're blasting down the trail and yous run across a hairpin coming up, and so you shut the throttle. This closes the butterfly valve. Yous and your 400lb baby (the bike, non the other love of your life), are still rolling with inertia, keeping the engine revs high. Now it can't become the mixture it's trying to suck in because the butterfly valve is airtight, blocking the air catamenia. To compensate for this there's an air jet in the lower diaphragm bedroom that transfers ambient pressure to one side of the coasting enricher'southward spring loaded cut off valve. The backlog vacuum in front of the butterfly valve is transferred to a drilling that leads to the other side of the cutting off valve. This sucks it open, assuasive the pilot jet to feed more fuel to the engine preventing an overly

diaphragm bedroom that transfers ambient pressure to one side of the coasting enricher'southward spring loaded cut off valve. The backlog vacuum in front of the butterfly valve is transferred to a drilling that leads to the other side of the cutting off valve. This sucks it open, assuasive the pilot jet to feed more fuel to the engine preventing an overly

lean condition. (Popular. Pop. Pop.) Enough theory. Fourth dimension to get your hands dirty.

Part II - Tuning and Options

WARNING!

Exercise NOT tamper with your carb. Unless it'south fourth dimension to clean or overhaul it, you've changed the frazzle or airfilter, you lot need to troubleshoot it,or the Child in y'all just has to know, "how does it go?" When troubleshooting the carb, remember it'due south job is to mix fuel and air to a specific ratio for the engines consumption.At that place are many things that can cause an imbalance in your mixture besides the carb itself. Things like a leaking or pinched hose, valve clearance, a dirty air cleaner, removing the airbox lid, even running out of fuel. Anything that affects your large pumpas it sucks and blows, affects your mixture. Before blaming the carb, eliminate equally many other variables as you lot can.

ON or OFF - Practise I Take To?

Open the drain bolt to empty the float bowl. Remove the throttle cables, loosen the kicking clamps and rotate the bottom of the carb towards the left side of the cycle. Exist careful that you don't smash the plastic starter cap nut,

it'due south 12 bucks for a new one. Remove the top, knowing that the cap will fly off from spring pressure level when you remove the final screw. Pull the diaphragm valve out, drill it, and then put in the new needle. Don't force the diaphragm valve and needle downwards into the carb body when reinstalling information technology. The needle should easily drop into the needle jet. If it doesn't, pull information technology out and endeavour once again. Button it upwards and move on to the bottom of the carb.

Drill out the cap on the pilot spiral. Remove the 4 screws on the float bowl and remove information technology. Unscrew the principal jet only, leaving the needle jet holder in place. Screw in the new main jet and supercede the float bowl. Rotate the carb, tighten the boot clamps, and bleed screw. You're done.

The manufactory method of removing the carb from the bike isn't very convenient for trailside repair, and I'm lazy anyway, then I don't like to swing the subframe unless I accept to. If it's something that requires the carb to come up off, loosen the kicking clamps,disconnect the throttle cables, remove starter (choke) plunger from the ;handlebar then the carb, fuel hose, and vacuum hose. Then muscle it out from the right side of the bike starting with the terminate nearest the airbox (click hither for enlarged view). If yous don't know your own force, be aware that your carb is cast aluminum and tin can crack or gall if mishandled. Jake warned of niggling parts that tin easily be lost. I've noticed 2 parts that are but waiting to laugh at you. The needle jet collar and the airplane pilot screw O-ring both tend to stick in place. Information technology may be that as the thin picture of fuel surrounding them dries, the surface tension is finally reduced to a point where they tin fall out on their own, even when you're not around to see it. You lot wouldn't be the showtime or last person to be missing these disquisitional parts. Click hither for to see more assembly detail.

FLOAT HEIGHT

Drain the float basin to check for water or other impurities. The float level is the beginning affair that needs to exist checked when tuning your carb. If the level is too high, information technology can cause a rich condition, besides low and information technology can crusade a lean status. If it'south non set correctly, any other adjustments you make may accept to be redone.

Kawasaki would love to sell y'all their gauge to cheque the height. But get a clear hose and attach it to the carb bleed valve at the bottom and tape it upward to the side of your carb. Put the bike on the eye stand or otherwise make information technology level. Employ an auxiliary gas can in a higher place the carb then it volition continue to dump fuel. Or use the vacuum line and suck on it to open up the petcock valve. Open up the carb drain valve. Get a gauge or ruler and measure out correct where the carb body meets the float bowl to the level in the hose. Don't motion the hose after you open the drain, or information technology could cause the reading to be loftier.

Hopefully you'll come across 0.5mm above the base of operations of the carb body, +/-1mm, (only about .08" variance).If information technology needs to be adjusted, and the carb is already off the bike, the method in the factory manual is the easiest way to gear up the float height. It can also be washed without removing it from the bike.

Afterward disconnecting the gas and draining the fuel out, you'll need to rotate the carb and take the four screws off the bottom of the bladder bowl and remove information technology. So push button the pin out of the float boss and gently remove the float and float valve. The bladder valve will be hanging loosely on the float by a very thin wire that slips over a metal tang on the float. Bending this tang on the float (non the wire on the float valve), will raise or lower your float level. Just a small bend makes a big difference in the level, so it'due south all-time to make minute movements here.

Earlier bending annihilation, visually inspect the safety tip on the float valve and spray some carb cleaner and compressed air in the valve seat, to brand sure nothing is blocking it open. Also see that the plastic float isn't leaking and filling with gas. So bank check the level over again and rebend if needed.

Pilot SYSTEM TUNING

The ideal way to tune it would be to use the M&Northward air/fuel monitor, a Colortune spark plug, or something like. But you can get close to this by using the following method.

Gently turn the pilot mixture clockwise until it'south seated. Back information technology out ii total turns. Now thoroughly warm the engine and prepare the idle to 1300 RPM with the big throttle end screw on the right side of the carb. Get Jake's carb tool and slowly dorsum the pilot screw out until the idle starts to slow and note the total number of turns out from it's seat. Now slowly spiral the pilot screw dorsum in until the idle once again starts to slow. Do the math and set your airplane pilot screw between the two points where the idle slowed. If you lot experience popping or it hesitates to return to idle, experiment by turning the airplane pilot screw out more.

Chief SYSTEM TUNING

Opening the butterfly valve with the throttle grip brings the main system into play. More air through the depression increases the vacuum to both the peak diaphragm bedroom and needle jet. As the vacuum in the peak chamber causes the diaphragm valve to raise in the low, the needle which is attached to the valve, is pulled further out of the needle jet. The higher the needle goes, the progressively thinner cross section of the needle allows more than fuel to pass through the needle jet.

Opening the butterfly valve with the throttle grip brings the main system into play. More air through the depression increases the vacuum to both the peak diaphragm bedroom and needle jet. As the vacuum in the peak chamber causes the diaphragm valve to raise in the low, the needle which is attached to the valve, is pulled further out of the needle jet. The higher the needle goes, the progressively thinner cross section of the needle allows more than fuel to pass through the needle jet.

The Dynojet needle has five grooves, #1 at the summit, to #v closest to the needle tip. Putting the E clip towards the meridian leans the mixture because a thicker portion of the needle is blocking fuel flow through the needle jet. Placing the Due east clip closer to the tip enrichens the mixture past pulling the needle further from the needle jet, exposing a thinner portion to allow more fuel period.

The transmission shows the KLR600 needle has these grooves, merely the KLR650 comes

The transmission shows the KLR600 needle has these grooves, merely the KLR650 comes

stock with no grooves for adjustments. The needle jet size also affects flow.

The last factor in the chief system is the Principal Jet. When the diaphragm

valve is fully raised and the needle is at it's farthest betoken out of the

needle jet, the Principal Jet size has the most influence on quantity of fuel

delivered. Below 3/4 throttle there's little difference between a 136 and

a 150 main jet. At total throttle in that location is a huge divergence. (Higher

numbered jets take a bigger hole.) Some of the Listers on the klr650 news

grouping accept taken to Shimming the stock needle and precisely drilling the

stock main jet with some success. One fixed a torn diaphragm valve with a

tire tube patch!

OPTIONS

It's hard to tune the airplane pilot screw with the carb in place and the engine running. Jake created a tool just for this. You tin can call him at (435) 387-5575. I'grand testing a new screw that was developed for the Harley only seems to be working and then far on the KLR. I'll post the results in a future update.

It's hard to tune the airplane pilot screw with the carb in place and the engine running. Jake created a tool just for this. You tin can call him at (435) 387-5575. I'grand testing a new screw that was developed for the Harley only seems to be working and then far on the KLR. I'll post the results in a future update.

Besides the Dynojet kit, you can also employ the Dial-A-Jet

Besides the Dynojet kit, you can also employ the Dial-A-Jet

Originally posted by Redondo Ron on a now defunct AOL website in December, 1998. The pictures and text are all his. Many thanks.

Source: https://gadgetsfixitpage.com/article.php/the-keihin-cvk-40-carburetor

Posted by: cordovaworythe1986.blogspot.com

0 Response to "How To Repair A Carburetor On A 1998 Kawasaki 4 X 4 When It Runs Only On Choke"

Post a Comment